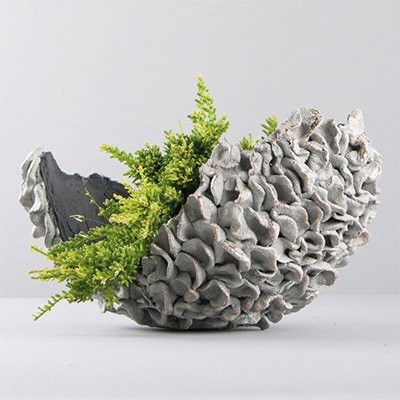

Instructions in 17 steps First cast the base with a hollow out of concrete. Then cast the bowl. The two concrete elements fit perfectly into each other.

Besides the articles listed below, you also need: Cooking oil, pebbles to weigh down the casting mould, empty can or pot as a stand for the big half-ball, support out of Crepla or cardboard, cooking oil, sieve, support out of Crepla or cardboard

And this is how it works: 1 ![]()

Step 1: Plinth

To start the preparation, put the square-shaped casting mould on a solid and even surface, so that it doesn’t wiggle and coat its inside with cooking oil. Coat well the outer side of the plastic half-ball ø 20 cm also with cooking oil.2 ![]()

Step 2

Pour about 250 ml of water in a plastic bucket and then gradually add approx. 2.5 kg of the creative-cement powder. Stir this mixture with a cooking spoon or the like until an uniform and castable mass is obtained.3 ![]()

Step 3

Fill the prepared big square-shaped casting mould with the casting compound up to the desired height (at best, do not pour quite up to the top). Let the mixture rest for about 1-2 minutes. Finally, push immediately centrically & evenly the oiled plastic half-ball into the cast cement mixture – only as much as necessary to build later a slight hollow in the plinth. By careful moving back and forth, you can adjust even more its positioning. Finally, weigh down the casting mould to the desired depth by means of the pebbles or small stones, and affix it additionally with a scotch tape.4 ![]()

Step 4

Let it dry out overnight. The next day, you can demould a part of the object. Firstly, demould carefully the plastic half-ball by bending and pulling it upwards slightly from all sides. Once it has been entirely removed from the casting object, let it dry once more for a few hours.5 ![]()

Step 5

Then you can demould the rest of the casting object from the mould by upturning the casting mould on the support out of Crepla or cardboard and then carefully press slightly with the palm of the hand on the casting object, so that the air penetrates between the casting object and mould. Tap the square-shaped casting mould gently on your support, so that the plinth out of cement becomes entirely detached from the mould.6 ![]()

Step 6

Allow it to harden. The curing time varies depending on the size and the temperature (one to several days).7 ![]()

Step 7

Small burrs and irregularities can be quickly & easily grinded with sandpaper8 ![]()

Step 8: Bowl

To start the preparation, put the big plastic half-ball on a solid and even surface (e.g. can, pot or the like), so that it doesn’t wiggle and coat its inside with cooking oil. Coat well the outer side of the small plastic half-ball also with cooking oil.9 ![]()

Step 9

Pour about 100 ml of water in a plastic bucket and then gradually add approx. 1 kg of the creative-cement powder. Stir this mixture with a cooking spoon or the like until an uniform and castable mass is obtained.10 ![]()

Step 10

Fill the prepared big plastic half-ball with the casting compound. Let the mixture rest for about 1-2 minutes. Finally, push immediately centrically & evenly the oiled smaller plastic half-ball into the cast cement mixture – until the desired depth is reached. By careful moving back and forth, you can adjust even more its positioning. Finally, weigh down the inner casting mould to the desired depth by means of the pebbles or small stones.11 ![]()

Step 11

Let it dry out overnight.12 ![]()

Step 12

The next day, you can demould a part of the object. Firstly, demould carefully the smaller plastic half-ball by bending and pulling it upwards slightly from all sides. Once it has been entirely removed from the casting object, let it dry once more for a few hours.13 ![]()

Step 13

Finally, demould the bowl out of cement by turning the half-ball around and bending slightly the upper edge outwards, so that the air penetrates between the casting object and mould. Tap the plastic half-ball gently on your working surface, so that the bowl out of cement becomes detached.14 ![]()

Step 14

Allow it to harden. The curing time varies depending on the size and the temperature (one to several days).15 ![]()

Step 15

Small burrs and irregularities can be quickly & easily grinded with sandpaper.16 ![]()

Step 16

The cast bowl fits now perfectly into the hollow of the cement-plinth!17 ![]()